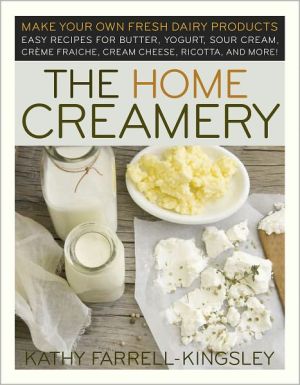

American Farmstead Cheese: The Complete Guide to Making and Selling Artisan Cheeses

This comprehensive guide to farmstead cheese explains the diversity of cheeses in terms of historical animal husbandry, pastures, climate, preservation, and transport-all of which still contribute to the uniqueness of farm cheeses today. Discover the composition of milk (and its seasonal variations), starter cultures, and the chemistry of cheese. The book includes:\ \ A fully illustrated guide to basic cheesemaking\ Discussions on the effects of calcium, pH, salt, and moisture on the...

Search in google:

Illustrated throughout with b&w photos, this volume describes the eight basic steps of small-scale cheesemaking. Kindstedt begins by tracing the origins of diverse cheese varieties in Europe and discussing their renaissance in the US in recent decades. He then addresses such topics as milk composition, starter cultures, and pasteurization. The final two chapters are devoted to business issues such as marketing and distribution. Kindstedt teaches courses on cheesemaking at the U. of Vermont. Annotation © 2006 Book News, Inc., Portland, OR

\ Excerpt from Chapter 10: The Art of Cheesemaking by Peter Dixon\ For an artisanal business to succeed, the product must be unique and consistently well made, and there must be a market for it. Therefore, artisan cheesemakers adhere to the traditional methods of their craft to bring forth the nuances in flavor that are generated through the intimate connection with the seasons and the environment. The finest cheese may vary, but it should vary within a certain standard if it is to be commercially marketable. Some artisan cheesemakers benefit from following traditions that produce these results, but most of us are relatively new at the game. For the less experienced cheesemakers, then, traditional methods should be supported by scientific principles to the extent necessary to make consistently high-quality cheese. It is important to note that many of the traditional artisan cheesemakers have strong support from the scientific community in their distinctive agricultural regions. The melding of craft and science is used to strengthen the activity on which their livelihood is based.\ A cheese such as Cheddar, which was once exclusively made by artisan cheesemakers in Great Britain, has largely turned into the product of an industrial process, though the craft of making Cheddar is still alive. Wheels of Cheddar sealed in cloth bandages, which represent the fruit of an artisan cheesemaker's labor, are still being made. In reading about the history of cheesemaking, we learns that 150 years ago the farm-made Cheddars were more variable in quality because cheesemakers differed in attitude and aptitude--that is, some were better at their craft than others. This could be attributed to many factors, most notably attention to cleanliness during milking and cheesemaking; construction of dairies, creameries, and cheese stores; and systems of cheesemaking. In the case of Cheddar, quality was improved by using methods based on scientific principles--such as the cheddaring process, hygiene, and temperature control during making and aging--that were developed by Joseph Harding in England from the 1850s onward.\ Joseph Harding dedicated many years to improving the standard of quality for British cheese. He used scientific principles to develop methods for making cheese that did away with some of the guesswork and exorcised the mysticism of certain traditional methods that produced haphazard results. In this way he was able to demonstrate that some "traditional" practices led to poor quality and also showed how to make significant and consistent improvements by following new practices based on an understanding of dairy science. At first cheesemakers were skeptical of his methods, but the string of blue ribbons collected by his family for their Cheddar cheeses proved him the wiser, and several of his daughters went on to consult and work for other cheese businesses in Great Britain and the United States (Cheke, 1959).\ This is the appropriate way for artisan cheesemakers to use science. It is now common practice to integrate scientific principles with traditional cheesemaking practices to better understand how cheese of the highest quality standard is made. This, in turn, enables dairying regions to maintain and develop viable economic enterprises that are centered on artisanal cheesemaking. The key is to produce cheese with a high level of quality, on which a reputation can be built, thereby ensuring marketability over the long term. As a cheesemaker myself--I make 20,000 pounds/9,000 kg of cheese a year for sale throughout New England--I need an approach that will reduce variability and build a reputation for quality. Therefore, I rely on science to enhance the art of cheesemaking. I use standardized rennet and pure starter cultures made in laboratories, and I test acidity regularly during the cheesemaking process. The rest of what I do is based on my knowledge of the craft, which has been built up over only 20 years.

Prefacexi1The Rhyme and Reason of Cheese Diversity: The Old World Origins1The Alpine Cheeses2The Soft Ripened Cheeses6Cheesemaking in England112Cheesemaking in the New World: The American Experience17Cheesemaking in the Colonies18The Northward Migration23The Westward Migration26The Decline29The Renaissance323Milk: The Beginning of All Cheesemaking37The Composition of Milk: Cow, Goat, and Sheep38Compositional Variation in Cheesemilk50From Milk to Cheese: Selective Concentration534Starter Culture: The Heart of Cheesemaking57Functions of the Starter Culture58Important Cheese Starters60Forms of Starter Culture61Sources of Starter Inconsistency and Failure65Secondary (Ripening) Cultures68Monitoring Starter Activity: Acidity Measurement715The Eight Basic Steps of Cheesemaking79Step 1Setting the Milk80Step 2Cutting or Breaking the Curd95Step 3Cooking and Holding the Curds99Step 4Draining the Whey; Dipping the Curds105Step 5Knitting the Curds108Step 6Pressing the Curds112Step 7Salting the Curds113Step 8Special Applications121Final Thoughts1226Chemical Composition: How It Shapes Cheese Identity and Quality123Calcium Content and pH124Salt Content128Moisture Content134Implications for Safety136Final Thoughts1377Ensuring Safety and Quality I: Hazard Analysis Critical Control Point and the Cheesemaking Process139Prerequisite Programs140The Seven Principles of HACCP141The Challenges of HACCP148Final Thoughts1518Ensuring Safety and Quality II: Controlling the Initial Chemical Composition153Establishing a Target Acidity Schedule154Acidity Testing as a Management Tool159Establishing Targets for Initial Composition1629The Pasteurization Dilemma173What Is Pasteurization?174Pathogens of Concern in Raw Milk175Milk Quality177Heat Treatment of Milk178Cheeses Made from Raw Milk180Previous Reviews on the Safety of Raw-Milk Cheeses181Improvement in Cheese Safety and Future Needs19010The Art of Cheesemaking197Artisanal Cheesemaking200Using Starter Culture and Rennet200Translating Recipes Using Direct Vat Set and Bulk Starters203Adding Starter to Milk205Cutting the Curds206Working and Firming the Curds209Pressing: Forming the Shape of the Cheese212Seasonal Dairying and Cheesemaking214Salting and Brining Cheese219Some Notes on Aging Cheese221Final Thoughts22411The Business of Farmstead Cheesemaking227A Lot of Humility Is a Good Thing227What Is the Vision?229Doing Some Homework229What Cheese Will You Make?230Control Equals Profit230Marketing and Communications233Sales and Distribution236Business Planning239Final Thoughts24412Putting It All Together: The Vermont Shepherd Story247The History of Vermont Shepherd247Vermont Shepherd Today256Frequently Asked Questions256Marketing260Final Thoughts261Further Reading263About the Contributors265Index269